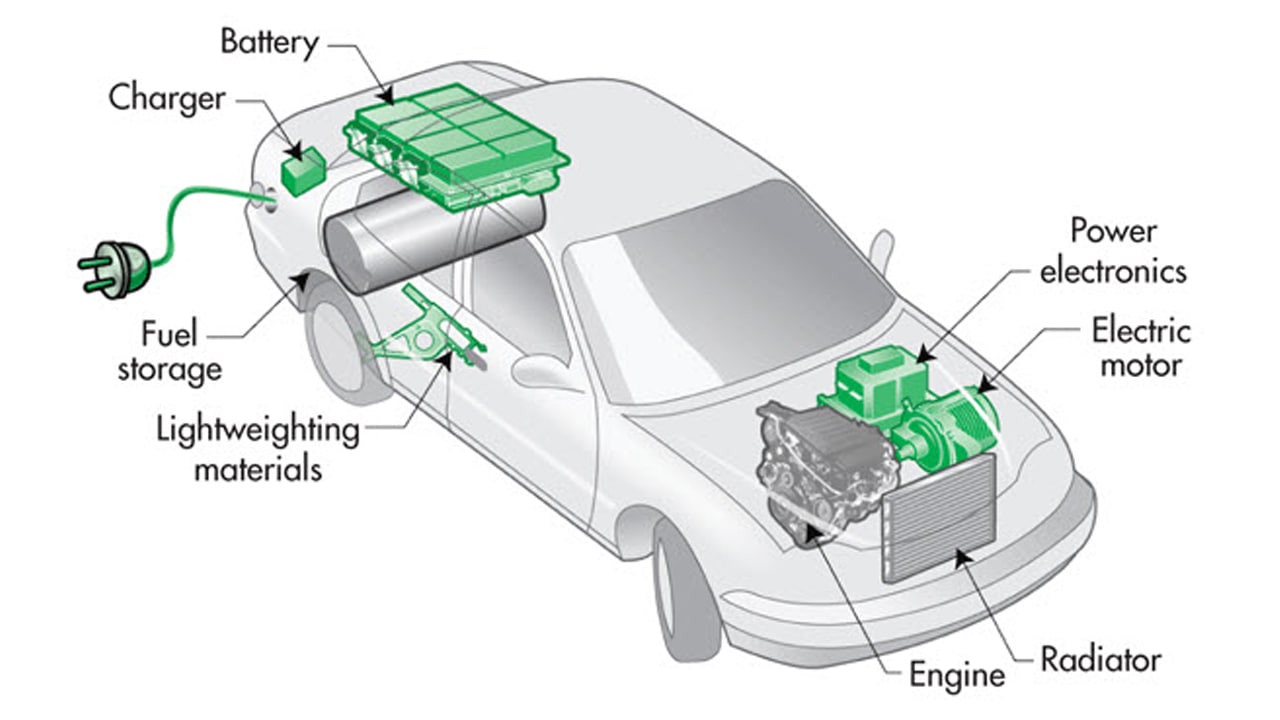

A recent report released by Strategy Analytics Electric Vehicle Service (EVS) pointed out that electric vehicles are facing consumer concerns about “range anxiety” and “charging anxiety”, and automakers’ response measures are further. Integrate components, take advantage of advances in power electronics to improve powertrain efficiency, and reduce charging time using the 800V+ power grid.

Join us on Telegram

Moreover, the report states that silicon carbide (SiC) is one of many wide-bandgap technologies used to improve the efficiency of switching power supplies to drive electric motors, receive charge through onboard chargers, and convert direct current.

Kevin Mak, a Principal Analyst at Strategy Analytics’ Global Automotive Practice (GAP), said: “As automakers adjust their operations to ‘all-electric’, competition between them has intensified. Wide-bandgap technologies, such as silicon carbide, make electric motors inverse The inverter is able to operate at a higher junction temperature, reducing its thermal management requirements.

Improving the performance of the power switch leads to a smaller inverter that spins the electric traction motor faster, improves torque output, and improves battery-electric powertrain performance Wide-bandgap technology also enables smaller components, which means improved powertrain size, weight, and power, while also making integrated systems more flexible. 800-volt technology also enables automakers to use Lighter cables, extracting power faster than using lower voltages.

Improving the performance of the power switch leads to a smaller inverter that spins the electric traction motor faster, improves torque output, and improves battery-electric powertrain performance Wide-bandgap technology also enables smaller components, which means improved powertrain size, weight, and power, while also making integrated systems more flexible. 800-volt technology also enables automakers to use Lighter cables, extracting power faster than using lower voltages.

Wide Bandgap or Wide Bandgap (WBG) refers to semiconductor devices such as Silicon Carbide (SiC) and Gallium Nitride (GaN) in which relatively high energies are required to move electrons from the atomic “valence” band to its ” “conduction” band, where electrons are available for current flow.

The measure of “band gap” is electron volts (eV), and silicon (Si) has a band gap value of about 1.1eV, compared to 3.2eV for SiC and 3.4eV for GaN. High bandgap values provide higher critical breakdown voltages and lower leakage currents, especially at high temperatures. Wide-bandgap devices also have better electron saturation speeds, allowing for faster switching. SiC also has particularly good thermal conductivity.